Seamlessly Integrating SCADA System and MES for Automotive Parts Factory

Advantech provides a complete and integrated solution which comprises a wealth of hardware products and a standardized open platform for System Integrators

Introduction:

Manufacturing Execution System (MES) was launched more than 20 years, and now has been widely applied to various manufacturing areas. In order to optimize the production process, MES usually combine with other underlying systems for providing visual, instant and paperless management applications. For instance, using Supervisory Control and Data Acquisition (SCADA) to gather real-time data and transfer them back to a central console can effectively control and monitor industrial equipments and manufacturing processes. Advantech provides a complete and integrated solution which comprises a wealth of hardware products and a standardized open platform for System Integrators and hence to make IT engineers who are unfamiliar with the industrial control design effortlessly obtain the underlying information as well as completing the vertical integration without worrying about software and hardware compatibility.

System Requirement:

Because of the increasingly tight delivery schedules and more and more short product life cycles, one of the world?s largest manufacturers of automotive parts was intending to improve its production operations and efficiency through IT management system and industrial control tools. Although the system contractor is a MES software provider and has extensive experiences in the field of manufacturing management and factory automation, it still needed a professional and trustworthy partner that offers a good interoperable SCADA solution to collect shop floor data. As a data gateway between the front-end equipments and MES application, the solution must provide the related hardware devices which have industry standards with durable and robust features to meet the factory?s specific requirements. Secondly, it required feature-rich and open architecture software to create user-friendly interface for facilitating on-site operation and remotely monitoring and to conveniently get data so that accelerating the project development.

System Description:

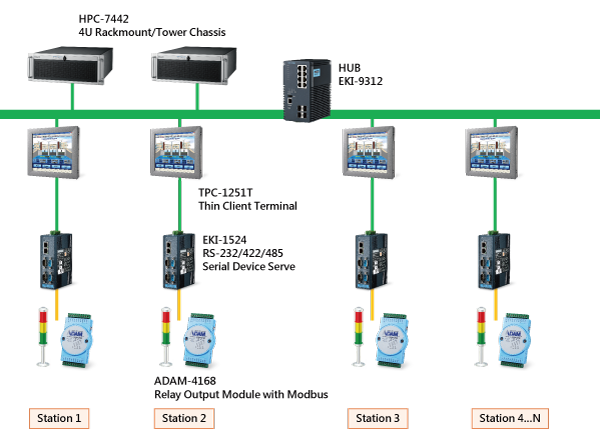

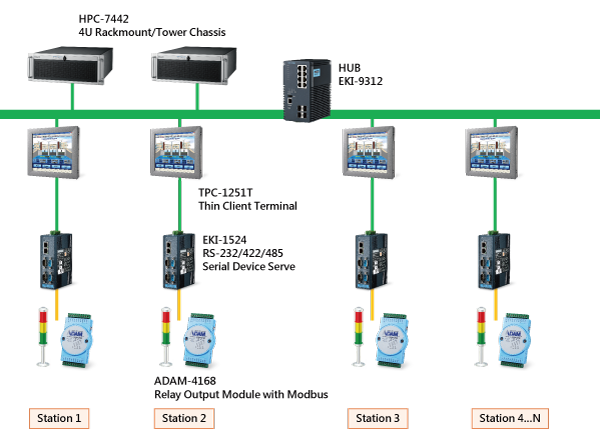

Due to being able to provide the comprehensive product portfolio, Advantech´s one-stop service fully satisfied this customer?s demands. First of all, the diverse hardware products were installed in the automotive parts factory, including the powerful industrial computer to run MES smoothly, touch screen terminal as a HMI (Human-Machine Interface) for operators in production lines, serial device server to transfer the signals and instructions, and multi-channel relay module to turn on/off indicator lights and alarm buzzer. All of Advantech´s devices have outstanding features such as broader operating temperature range, ESD protection, better noise immunity, high superior quality hardware design with high-standard protection, etc.

In terms of the software, Advantech´s WebAccess has advanced SCADA functions to optimize system functionality, e.g. supporting abundant drivers to configure and manage a variety of devices, distributed architecture with central database to record the production status and exchange data, data display with dynamically animated graphics to intuitively monitor and control each production line in real time. More importantly, it is an easy to learn and use software, and only two-day training course is enough to make IT programmers get the hang of it. By providing a highly agile design environment, it enables project designers to benefit from its openness and standardization, thereby seamlessly integrate MES with fewer burdens on the design process and minimizing the need of expert industrial control knowledge.

Project Implementation:

System Diagram

Conclusion:

With the widespread use of MES applications, enterprises have begun to change their traditional production process and control mode gradually. Accordingly, information collection becomes essential for management system development to success. Advantech?s versatile and useful SCADA software enables System Integrators to more efficiently collect data and develop their desired applications while reducing maintenance efforts and costs in consequence of adopting our rugged and stable hardware products. Ultimately, the vertically integrated applications not only allow end users to easily monitor and control production lines but also improving workflow and increasing productivity.

Manufacturing Execution System (MES) was launched more than 20 years, and now has been widely applied to various manufacturing areas. In order to optimize the production process, MES usually combine with other underlying systems for providing visual, instant and paperless management applications. For instance, using Supervisory Control and Data Acquisition (SCADA) to gather real-time data and transfer them back to a central console can effectively control and monitor industrial equipments and manufacturing processes. Advantech provides a complete and integrated solution which comprises a wealth of hardware products and a standardized open platform for System Integrators and hence to make IT engineers who are unfamiliar with the industrial control design effortlessly obtain the underlying information as well as completing the vertical integration without worrying about software and hardware compatibility.

System Requirement:

Because of the increasingly tight delivery schedules and more and more short product life cycles, one of the world?s largest manufacturers of automotive parts was intending to improve its production operations and efficiency through IT management system and industrial control tools. Although the system contractor is a MES software provider and has extensive experiences in the field of manufacturing management and factory automation, it still needed a professional and trustworthy partner that offers a good interoperable SCADA solution to collect shop floor data. As a data gateway between the front-end equipments and MES application, the solution must provide the related hardware devices which have industry standards with durable and robust features to meet the factory?s specific requirements. Secondly, it required feature-rich and open architecture software to create user-friendly interface for facilitating on-site operation and remotely monitoring and to conveniently get data so that accelerating the project development.

System Description:

Due to being able to provide the comprehensive product portfolio, Advantech´s one-stop service fully satisfied this customer?s demands. First of all, the diverse hardware products were installed in the automotive parts factory, including the powerful industrial computer to run MES smoothly, touch screen terminal as a HMI (Human-Machine Interface) for operators in production lines, serial device server to transfer the signals and instructions, and multi-channel relay module to turn on/off indicator lights and alarm buzzer. All of Advantech´s devices have outstanding features such as broader operating temperature range, ESD protection, better noise immunity, high superior quality hardware design with high-standard protection, etc.

In terms of the software, Advantech´s WebAccess has advanced SCADA functions to optimize system functionality, e.g. supporting abundant drivers to configure and manage a variety of devices, distributed architecture with central database to record the production status and exchange data, data display with dynamically animated graphics to intuitively monitor and control each production line in real time. More importantly, it is an easy to learn and use software, and only two-day training course is enough to make IT programmers get the hang of it. By providing a highly agile design environment, it enables project designers to benefit from its openness and standardization, thereby seamlessly integrate MES with fewer burdens on the design process and minimizing the need of expert industrial control knowledge.

Project Implementation:

| Product | Description |

| Advantech WebAccess | Browser-based HMI/SCADA Software |

| ADAM-4168 | Robust 8-ch Relay Output Module with Modbus |

| EKI-9312 | 8 Gigabit Ethernet ports and up to 4 fiber optic ports |

| TPC-1251T | 12.1" TFT LED LCD Intel® Atom? Thin Client Terminal |

| HPC-7442 | 4U Rackmount/Tower Chassis for EATX/ATX Motherboard with Up to 8 SAS/SATA HDD Trays |

System Diagram

Conclusion:

With the widespread use of MES applications, enterprises have begun to change their traditional production process and control mode gradually. Accordingly, information collection becomes essential for management system development to success. Advantech?s versatile and useful SCADA software enables System Integrators to more efficiently collect data and develop their desired applications while reducing maintenance efforts and costs in consequence of adopting our rugged and stable hardware products. Ultimately, the vertically integrated applications not only allow end users to easily monitor and control production lines but also improving workflow and increasing productivity.