Crushing Telematics: Data-driven Diagnostics & Productivity Management

Featuring vehicle diagnostic protocols, multiple interfaces and advanced customization functions, the VG710 delivers an ideal function to crushing telematics, helping OEMs remotely monitor their machines and improve productivity.

Background

In the world of aggregate production, pit and quarry operators are always seeking to increase efficiency, which is pushing OEMs of crushing machines to upgrade their systems. Telematics has almost been a must-have in today's crushing operations; manufacturers need to monitor their globally deployed machines, get their operation data, respond timely to idleness and technical problems, so that they can make the fullest use of their equipment, better serve their end customers, and thus maximize their financial gains and ROI.As crushers generally work in challenging and remote places featuring harsh physical environments (sand, dust, extreme temperatures, etc.) and poor connectivity, the telematics device is expected to working long hours outside, delivering fast and reliable connectivity to crushers, helping collect real-time location and operation status data to the back office/ cloud.

InHand's Solution of Crusher Telematics

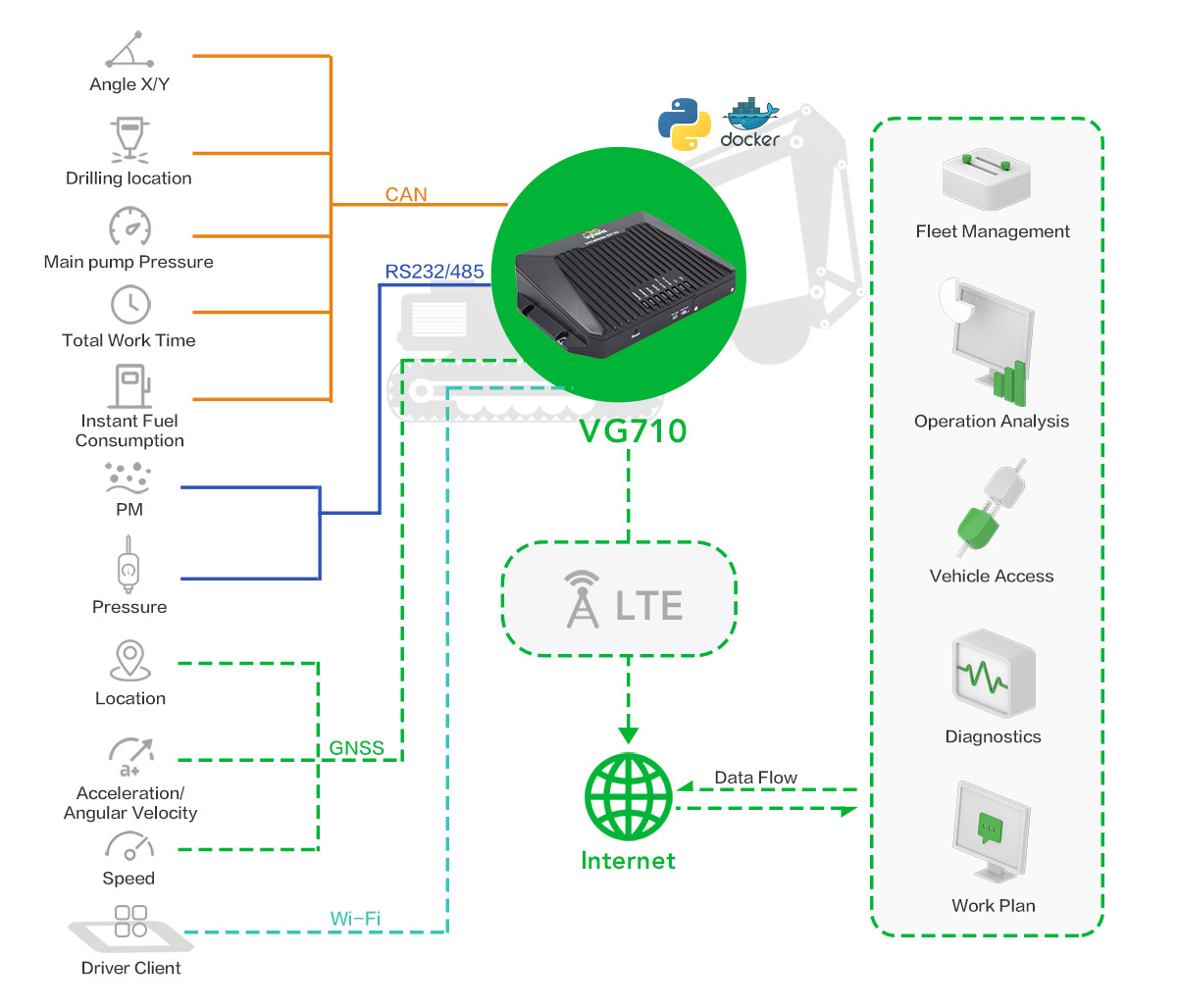

InHand's multi-network vehicle gateway VG710 is a perfect match for the scenario.

The crusher chassis is connected to the VG710 via CAN bus. Multiple ECUs on board acquire data of crusher operation status, such as angle, work time, oil, etc., while sensors collect environment variables such as PM and pressure and transmit to the gateway via serial ports. Built with GNSS module, the VG710 keeps locating the machine. After being processed locally, all the data are securely sent to the cloud. Manufacturers can thus analyze the data, check the crusher status, carry out maintenance, and find ways to improve productivity.

Advantages:

- Integrating OBD-II and J1939, with an environment for OEM self-developed protocols, the VG710 keeps track of the vehicle status and conducts real-time diagnostics, notifying users of problems and facilitating preventive maintenance.

- Built with multiple interfaces, including CAN, serial ports, Ethernet ports, Bluetooth, the VG710 offers expansion to the vehicle network by connecting a number of peripherals.

- The VG710 supports Modbus protocol and can be used to acquire business data from a variety of sensors.

- Python and Docker programmable, the VG710 offers flexible customization; FlexAPI enables easy integration to customers? local applications or 3rd party clouds.

- With support for major IoT clouds such as Azure and AWS, the VG710 makes it easy to migrate the vehicle data to the cloud.

- With multi-layered security mechanisms from edge to cloud, the VG710 offers strict data protection throughout the operation process, safeguarding business security.